Boiler Repair Solutions

Professional repair services for all commercial and industrial boiler systems.

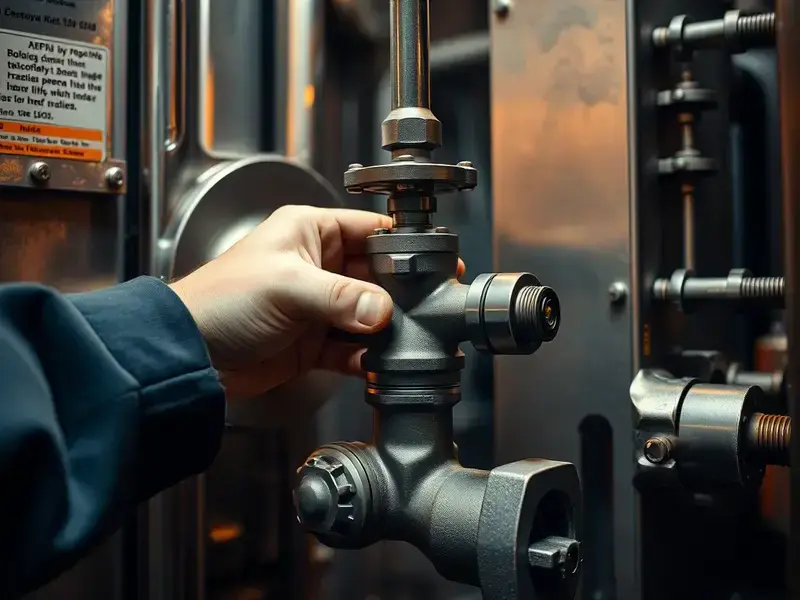

Expert Diagnosis & Repair

When your boiler system experiences issues, fast and accurate diagnosis is essential to minimize downtime and prevent further damage. Our certified technicians use advanced diagnostic equipment to identify problems quickly and implement effective solutions.

We service all major commercial boiler brands and models, including fire-tube, water-tube, and cast iron systems. Our service vehicles are fully stocked with common replacement parts, allowing us to complete most repairs in a single visit.

From simple valve adjustments to complex burner overhauls and heat exchanger replacements, we have the expertise to restore your system's performance and efficiency.

Our Repair Process

Systematic approach to every repair job for lasting results.

1. Comprehensive Diagnosis

We begin with a thorough system analysis, checking all components including burner operation, controls, safety devices, and combustion efficiency using specialized testing equipment.

2. Expert Repairs

Our technicians perform repairs using manufacturer-specified procedures and genuine parts. We work efficiently to minimize disruption while ensuring quality workmanship.

3. Testing & Verification

After repairs, we conduct comprehensive testing to verify proper operation, combustion efficiency, and safety device functionality before considering the job complete.

Common Repair Services

Full-spectrum repair capabilities for commercial boiler systems.

Burner & Combustion

- • Ignition system repair and replacement

- • Burner head cleaning and tuning

- • Gas train component service

- • Combustion analysis and adjustment

Controls & Electronics

- • Control board diagnosis and replacement

- • Sensor and probe calibration

- • Temperature and pressure control repair

- • Safety limit device testing

Hydronic Components

- • Pump repair and replacement

- • Valve service (gas, water, safety)

- • Expansion tank service

- • Feedwater system maintenance

Major Components

- • Heat exchanger inspection and repair

- • refractory and insulation service

- • Breeching and venting repair

- • Shell and tube replacement

Frequently Asked Questions

Answers to common questions about boiler repair services.

We understand that boiler failures can create critical situations, especially during cold weather. Our team offers 24/7 emergency response with typical arrival times of 2-4 hours for facilities within our service area. For priority maintenance customers, we guarantee even faster response times and priority scheduling.

The most common causes of boiler breakdowns include lack of regular maintenance leading to component wear, ignition system failures from dirty or faulty parts, control malfunctions due to electrical issues or sensor failures, and water chemistry problems causing scale buildup or corrosion. Regular preventive maintenance significantly reduces the likelihood of unexpected breakdowns.

Absolutely. After our diagnostic assessment, we provide a detailed written estimate that outlines the recommended repairs, parts needed, and associated costs. We proceed only after you approve the work. For emergency situations, we provide preliminary cost information and update you if additional issues are discovered during repair.

Our technicians are trained and certified to service all major commercial and industrial boiler brands including Cleaver-Brooks, Fulton, Hurst, Raypak, Lochinvar, Weil-McLain, and many others. We also have experience with older and legacy systems from manufacturers that may no longer be in operation.

Need Boiler Repair?

Our certified technicians are ready to diagnose and repair your system. Call now for prompt, professional service.